ETI.sa, a Tunisian industrial specialized in enamelling tanks for solar water heaters, sanitary hot water tanks and electric water boilers and plates for culinary items and signage.

Hot Water Tanks

Enamelling tanks for slar water heaters and electric boilers.

Nameplates

Manufacturing street signs and enamelled steel road signs.

Cookwares

Enamelled cast iron utensils and kitchen ware.

WHO ARE WE

Enameled Technology Industry (ETI.sa), located in the Industrial Area of Zriba Zaghouan in Tunisia, is a limited company with a share capital of 1.4 Million DT and a total investment of 3 500 000 TDN. Its production unit covers 3000 m², including 500 m² for administrative and common permises.

ETI.sa is the national and regional leader in enameling tanks for water solar heaters (SWH), sanitary hot water tanks and water heaters. ETI.sa is also active in the enameling of signage boards, culinary items and household appliances…

ETI.sa is the first and only one of its kind in Africa and in the Arab World. It is equipped with high-level German technology offering a range of high quality tanks with a 10-year warranty…Find out more

Read More

DISCOVER OUR STRENGTHS

German technology

High quality material

Respect of standards

Customer satisfaction

Quality control throughout the manufacturing process Discover our Process

OUR PROCESS

1. Preparation of raw tanks

This operation involves controlling the tank and cleaning its inner surface to remove impurities.

2. Mix preparation

The mix is controlled, after four to six hours of kneading, the control parameters are the density the PU.

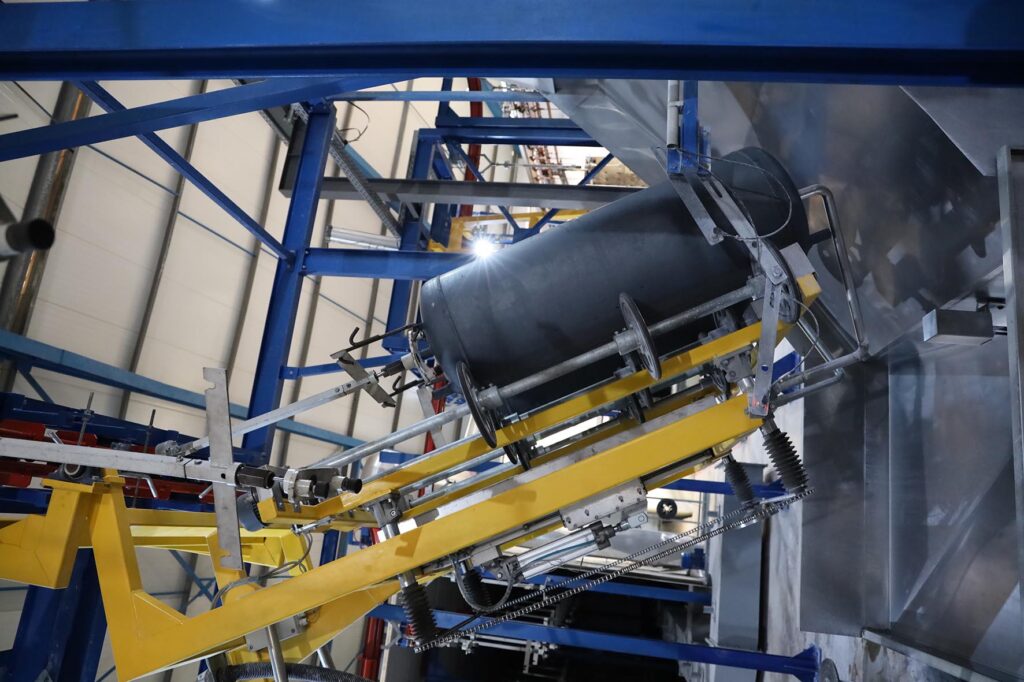

3. Loading tanks

The loading of the tanks is done using the loading manipulator and the application conveyor.

4. Application of enamel

The application is 100% automated since the loaded tanks will follow the steps programmed in the application automaton.

5. Drying the tanks

The tanks are then inserted into the dryer. The drying temperature is set at between 70 and 140 degrees Celsius.

6. Control of dried tanks

All tanks are checked at the exit of the dryer to check if the enamel is properly applied.

7. Transfer of the tanks

The tanks are then routed to the furnace through their transfer to the firing conveyor.

8. Firing of tanks

9. Control of enamelled tanks

A sample of tanks is tested for each series, the tests are carried out with reference to the German standard.

General Manager’s Statement

Enameled Technology Industry is the result of a deep attachment to the work values, performances and respect for the environment with which we are in a perpetual interaction.

It is above all, an expertise and a team spirit whose challenges are the satisfaction of our customers and the professional improvement of and progress our collaborators.

Our success is due to our ability to adapt our working methods to the most recent techniques and technologies in order to bring the expected added value to our partners in terms of benefits, anticipating needs, timeliness in execution and especially in terms of qualitative contributions of our products.

If our company today occupies a place of choice in the enameling sector in Tunisia and the region, it is thanks to a development strategy that adapts our activity to the market changes and meets the expectations of our environment.

Due to its leadership position, ETI.sa is aware of the socio-economic issues, continues its approach for progression and improvement and seeks to meet new challenges by constantly committing to the full satisfaction of its relevant takeholders and in particular its customers as indicated in our quality policy.

Read more

Sami MARROUKI

Energy engineer, Chief executive officer